-

admin

- January 13, 2026

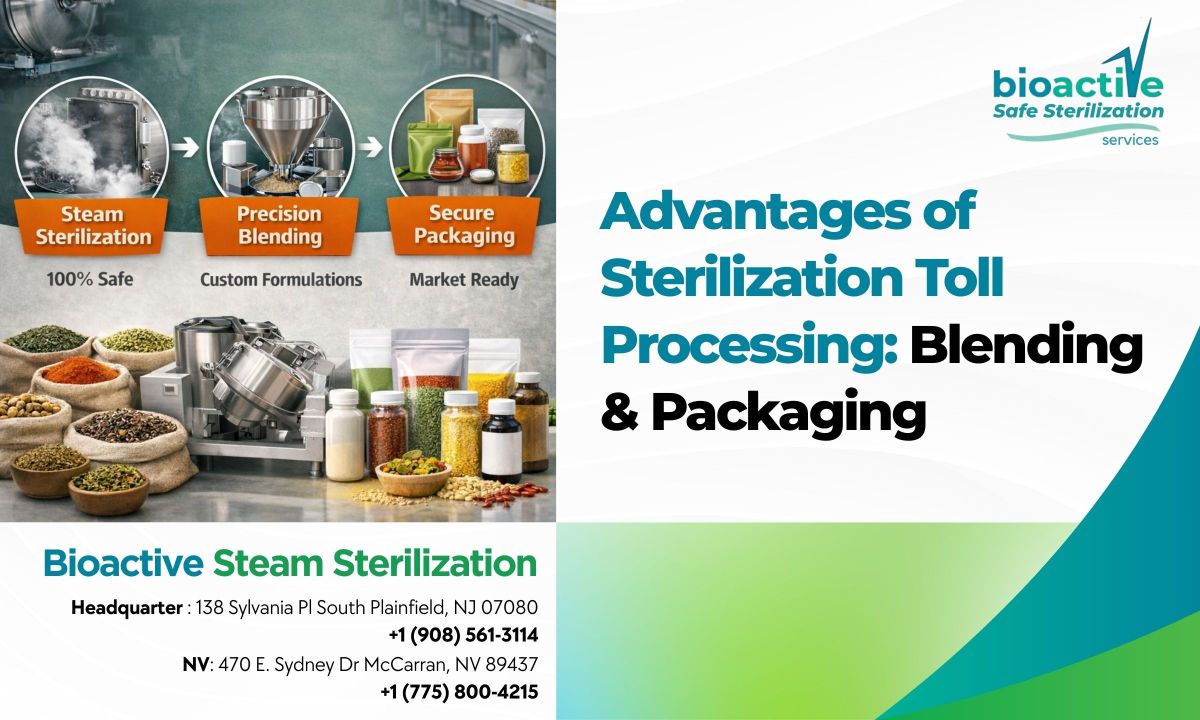

Advantages of Sterilization Toll Processing Blending & Packaging

In today’s regulated food, spice, herbal, and nutraceutical industries, manufacturers must ensure product safety, consistency, and compliance while keeping production efficient and cost-effective. This is where sterilization toll processing plays a critical role.

At Bioactive Safe Sterile, we provide end-to-end sterilization toll processing services in the USA, combining steam sterilization, precision toll blending, and packaging under one roof. This streamlined approach helps brands reduce risk, save time, and scale production without managing multiple vendors.

What Is Sterilization Toll Processing

Sterilization toll processing is a single-facility manufacturing model where raw materials undergo:

- Steam sterilization

- Controlled toll blending

- Secure packaging

within the same FDA-compliant facility.

This ensures better hygiene control, traceability, and operational efficiency across the entire production cycle.

1. Superior Product Safety With Steam Sterilization

Microbial contamination is a major concern in spices, herbs, and nutraceutical powders. Sterilization toll processing ensures that steam sterilization is the first controlled step, preventing contamination from the start.

Bioactive’s Sterilization Advantage:

- FDA-compliant steam sterilization services in the USA

- Chemical-free microbial reduction

- Effective against Salmonella, E. coli, and mold

- Maintains nutritional integrity and product potency

By keeping sterilization, blending, and packaging in one facility, the risk of recontamination is significantly reduced.

2. Consistent Formulations Through Toll Blending

After sterilization, materials move directly into precision toll blending, ensuring:

- Uniform ingredient distribution

- No exposure to external environments

- Better batch-to-batch consistency

Bioactive Toll Blending Capabilities:

- Custom and standardized blends

- Small to bulk batch processing

- Nutraceutical, herbal, and functional food formulations

This controlled flow improves product reliability and formulation accuracy.

3. Faster Production & Reduced Lead Time

When sterilization, blending, and packaging are handled by different vendors, delays are common. Sterilization toll processing eliminates these inefficiencies.

Key Benefits:

- No inter-facility transportation delay

- Faster production cycles

- Quicker market readiness

This makes sterilization toll processing ideal for export-focused and high-volume manufacturers.

4. Improved Traceability & Regulatory Compliance

Sterilization toll processing simplifies compliance by maintaining complete batch-level traceability within a single system.

Compliance Support at Bioactive:

- FDA-aligned processes

- USDA Organic-compatible handling

- GMP-compliant workflows

- Documentation support for global exports

This is critical for brands supplying US, EU, and international markets.

5. Secure Packaging for Market-Ready Products

Packaging within the same sterilization toll processing facility ensures:

- Hygienic handling

- Accurate labeling

- Reduced contamination risk

Bioactive Packaging Solutions:

- Bulk and retail packaging

- Private labeling

- Export-ready packaging formats

- Custom pack sizes

Your product leaves the facility fully processed and market-ready.

6. Ideal for Nutraceutical, Spice & Herbal Brands

Sterilization toll processing is best suited for:

- Nutraceutical manufacturers

- Spice exporters

- Herbal and botanical brands

- Functional food companies

- Growing brands scaling to bulk production

Bioactive acts as a single trusted processing partner, simplifying operations and ensuring quality.

Why Choose Bioactive for Sterilization Toll Processing?

Bioactive Sterilization is a USA-based manufacturer offering complete sterilization toll processing solutions for domestic and international clients.

What Makes Bioactive Different:

- Steam sterilization, blending & packaging under one roof

- FDA-compliant sterilization toll processing

- Custom formulations and toll blending

- Export-ready documentation

- Scalable bulk processing solutions

We help brands deliver safe, compliant, and high-quality products to global markets.

Final Thoughts

Sterilization toll processing is a smart, scalable solution for manufacturers seeking efficiency without compromising safety or quality. By combining steam sterilization, toll blending, and packaging in a single controlled environment, brands can reduce costs, improve compliance, and accelerate growth.

With Bioactive Sterilization, you gain more than a service—you gain a reliable toll processing partner.